Can ball screws be used in vertical applications? That's a question I get asked a lot as a ball screw supplier. In this blog post, I'm gonna break down everything you need to know about using ball screws in vertical setups.

First off, let's talk about what ball screws are. They're mechanical linear actuators that convert rotational motion into linear motion with high efficiency. They consist of a screw shaft, a nut, and a series of ball bearings that roll between the screw and the nut. This design reduces friction and allows for smooth and precise movement.

Now, when it comes to vertical applications, there are some unique challenges. Gravity is the main culprit here. In a vertical setup, the ball screw has to work against gravity to move the load up and support it when it's stationary. This means there are some important factors to consider.

Load Capacity

One of the key things to look at is the load capacity of the ball screw. In a vertical application, the weight of the load is constantly pulling down on the screw. You need to make sure the ball screw you choose can handle the static and dynamic loads. For example, if you're using a ball screw to lift a heavy industrial part, you gotta pick one with a high enough load rating. Otherwise, it could lead to premature wear and even failure.

Backdriving

Backdriving is another issue in vertical applications. Backdriving happens when the load causes the screw to rotate in the opposite direction of the intended motion. In a vertical setup, gravity can cause backdriving if the ball screw isn't properly designed or if the system doesn't have the right brakes or holding mechanisms. To prevent backdriving, you might need to use a self - locking ball screw or add a brake to the system.

Lubrication

Lubrication is crucial for the smooth operation of ball screws, especially in vertical applications. In a vertical setup, the lubricant has to be able to stay in place and provide adequate protection against friction and wear. Gravity can cause the lubricant to drip or flow down, leaving parts of the ball screw unlubricated. You need to choose a high - quality lubricant and a proper lubrication system that can ensure continuous lubrication.

Mounting and Alignment

Proper mounting and alignment are essential for the performance of ball screws in vertical applications. Any misalignment can cause uneven loading on the ball bearings, leading to increased wear and reduced efficiency. You have to make sure the ball screw is mounted securely and aligned correctly with the load and the driving mechanism.

Advantages of Using Ball Screws in Vertical Applications

Despite the challenges, there are some great advantages to using ball screws in vertical setups.

High Precision

Ball screws offer high precision in linear motion. This is really important in applications where accurate positioning is required, like in CNC machines or robotic arms. In a vertical application, you can precisely control the height of the load, which is crucial for tasks such as assembly or material handling.

High Efficiency

They're also very efficient at converting rotational motion into linear motion. This means less energy is wasted, and you can achieve the desired movement with less power. In a vertical application, this can result in cost savings and reduced wear on the driving motor.

Smooth Operation

Ball screws provide smooth and quiet operation. This is beneficial in applications where noise and vibration need to be minimized, such as in medical equipment or laboratory instruments.

Types of Ball Screws for Vertical Applications

There are different types of ball screws that can be used in vertical applications.

Samll Ball Screw

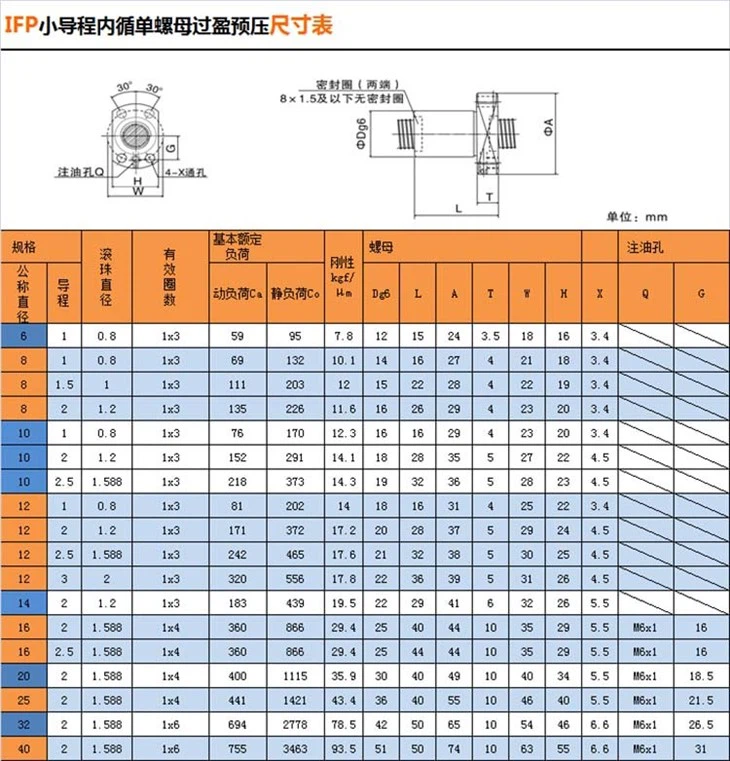

Small ball screws are great for applications where space is limited. They can still provide high precision and efficiency, even in vertical setups. They're often used in small - scale automation equipment or in applications where the load is relatively light.

Custom Ball Screw

For more complex vertical applications, custom ball screws might be the way to go. You can get them designed to meet specific requirements, such as a particular load capacity, length, or lead. This allows you to optimize the performance of the ball screw for your specific application.

Selecting the Right Ball Screw Supplier

Choosing the right ball screw supplier is crucial. You want a supplier who can offer high - quality products, technical support, and quick delivery. As a ball screw supplier, I know how important it is to understand the customer's needs and provide the best solutions.

Ball Screw Suppliers

There are many ball screw suppliers out there, but not all of them are created equal. Look for a supplier with a good reputation, extensive experience, and a wide range of products. A reliable supplier can help you select the right ball screw for your vertical application and provide support throughout the installation and operation process.

Conclusion

So, can ball screws be used in vertical applications? Absolutely! But you need to carefully consider the load capacity, backdriving, lubrication, and mounting. By choosing the right type of ball screw and working with a reputable supplier, you can overcome the challenges and take advantage of the many benefits that ball screws offer in vertical setups.

If you're looking for ball screws for your vertical application, I'd love to help. Contact me to discuss your requirements and let's find the perfect ball screw solution for you.

References

- "Mechanical Design Handbook" by Robert C. Juvinall and Kurt M. Marshek

- "Motion Control Basics" by Dana W. Coester