Hey there! As a supplier of Cnc Slide Rails, I often get asked about the accuracy of these crucial components. So, let's dive right in and explore what the accuracy of Cnc Slide Rails really means.

First off, what are Cnc Slide Rails? Well, they're an essential part of CNC (Computer Numerical Control) machines. These rails provide a smooth and stable path for the moving parts of the machine, like the cutting tools or the workpiece holders. Think of them as the tracks that a train runs on, but for a high - tech machining environment. You can check out more about Cnc Slide Rails on our website.

Accuracy in Cnc Slide Rails is all about how precisely they can guide the moving parts of a CNC machine. There are a few key aspects to consider when talking about this accuracy.

Positional Accuracy

One of the most important factors is positional accuracy. This refers to how closely the moving part of the machine can reach and stay at a specific position along the rail. In a CNC machining process, even the slightest deviation can lead to parts being produced out of spec. For example, if you're making a precision part for an aerospace application, a small error in the position of the cutting tool can mean the difference between a part that meets the strict quality standards and one that has to be scrapped.

The positional accuracy of Cnc Slide Rails is typically measured in micrometers (μm). High - quality Cnc Slide Rails can achieve positional accuracies in the range of a few micrometers. This level of precision is crucial for industries that require extremely tight tolerances, such as medical device manufacturing, where a tiny error can have a big impact on the functionality of the final product.

Repeatability

Repeatability is another vital aspect of accuracy. It's about whether the slide rail can consistently move the machine part to the same position over and over again. Imagine you're mass - producing a particular part. You need each part to be identical to the others. If the Cnc Slide Rail isn't repeatable, then each part might come out slightly different.

Good Cnc Slide Rails have a high repeatability rate. They can move the machine components to the same position within a very small margin of error, often within a few micrometers as well. This ensures that the manufacturing process is consistent and that the end - products meet the required quality standards.

Straightness

Straightness is also a key factor in the accuracy of Cnc Slide Rails. The rail needs to be as straight as possible so that the moving part can travel in a perfectly linear path. Any deviation from a straight line can cause the machine to cut or shape the workpiece at an incorrect angle, leading to parts that don't fit together properly or don't function as intended.

Manufacturers use advanced techniques to ensure the straightness of Cnc Slide Rails. They might use precision grinding or honing processes to achieve the desired level of straightness. Even the slightest curve or bow in the rail can have a significant impact on the accuracy of the machining process.

Factors Affecting Accuracy

There are several factors that can affect the accuracy of Cnc Slide Rails. One of the main factors is the quality of the materials used. Rails made from high - grade steel or other advanced alloys tend to have better accuracy and durability. These materials can withstand the wear and tear of continuous use and maintain their shape and dimensions over time.

The manufacturing process also plays a crucial role. Precision machining techniques, such as computer - controlled grinding and lapping, are used to create Cnc Slide Rails with high accuracy. Any errors in the manufacturing process can lead to inaccuracies in the final product.

Another factor is the lubrication of the slide rails. Proper lubrication reduces friction between the moving parts and the rail, which helps to maintain accuracy. If the rails aren't lubricated correctly, there can be increased wear, which can lead to a decrease in accuracy over time.

Different Types of Cnc Slide Rails and Their Accuracy

There are different types of Cnc Slide Rails, each with its own characteristics and levels of accuracy.

Roller Guideways are one type. They use rollers to reduce friction and provide smooth movement. Roller guideways can offer high - speed operation and good load - carrying capacity. In terms of accuracy, they can achieve relatively high levels of positional accuracy and repeatability, especially when properly maintained.

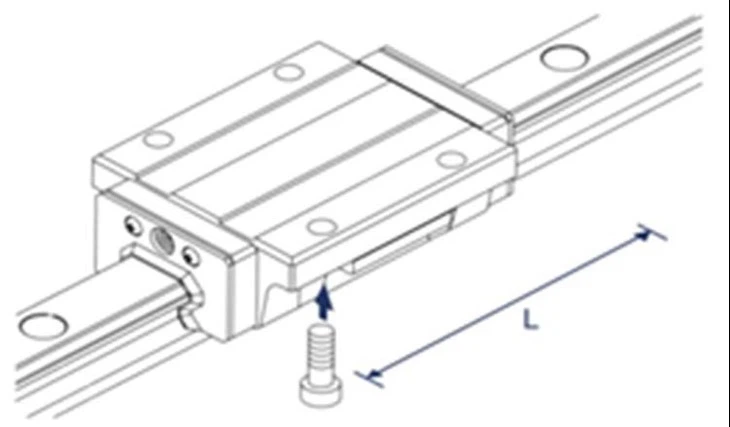

Another type is the Motion Linear Guide. These guides are designed to provide precise linear motion. They often use advanced bearing technologies to ensure smooth and accurate movement. Motion linear guides are known for their high accuracy and are commonly used in applications where precision is of the utmost importance.

Importance of Accuracy in Different Industries

The accuracy of Cnc Slide Rails is crucial in various industries. In the automotive industry, for example, precision - machined parts are essential for the proper functioning of engines, transmissions, and other critical components. Cnc Slide Rails with high accuracy ensure that these parts are produced to the exact specifications, which helps to improve the performance and reliability of vehicles.

In the electronics industry, where components are getting smaller and more complex, the accuracy of Cnc Slide Rails is even more critical. The production of printed circuit boards (PCBs) and microchips requires extremely precise machining to ensure that the tiny components are placed and connected correctly.

In the mold - making industry, Cnc Slide Rails are used to create molds for a wide range of products, from plastic containers to automotive body parts. The accuracy of the slide rails determines the quality of the molds, which in turn affects the quality of the final products.

How We Ensure the Accuracy of Our Cnc Slide Rails

As a supplier of Cnc Slide Rails, we take accuracy very seriously. We start by using only the highest - quality materials. Our engineers carefully select the alloys and steels that offer the best combination of strength, durability, and dimensional stability.

We have a state - of - the - art manufacturing facility where we use the latest precision machining techniques. Our production process is closely monitored at every stage to ensure that the Cnc Slide Rails meet the strictest quality standards. We use advanced measuring equipment to check the positional accuracy, repeatability, and straightness of each rail before it leaves our factory.

We also provide detailed maintenance instructions to our customers. Proper maintenance, including regular lubrication and cleaning, is essential for maintaining the accuracy of the Cnc Slide Rails over their lifespan.

Conclusion

In conclusion, the accuracy of Cnc Slide Rails is a multi - faceted concept that includes positional accuracy, repeatability, and straightness. It's a critical factor in the performance of CNC machines and the quality of the products they produce. Different types of Cnc Slide Rails, such as roller guideways and motion linear guides, offer varying levels of accuracy depending on the application.

If you're in the market for high - quality Cnc Slide Rails that offer excellent accuracy, we'd love to hear from you. Whether you're in the automotive, electronics, or any other industry that requires precision machining, we can provide you with the right solution. Contact us to start a discussion about your specific needs and let's work together to achieve the best results for your manufacturing processes.

References

- "Precision Engineering in Manufacturing", Smith, J., 2020

- "CNC Machining Handbook", Brown, A., 2019

- "Linear Motion Technology", Green, R., 2018